When most people think of knife sharpening, they imagine simply shaving the edge a little to make it pointy again.

This is especially true for people overseas, where the culture of sharpening with whetstones is not very familiar.

Sharpening with water and a whetstone may look like a simple task. Many assume that just rubbing the edge lightly against the stone will instantly restore sharpness. However, this alone is not enough to maintain a truly fine cutting edge.

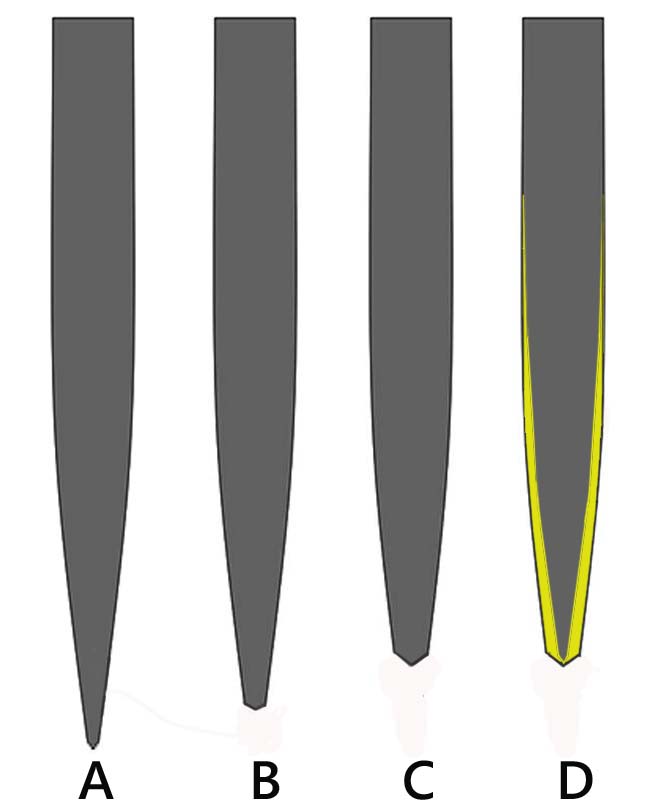

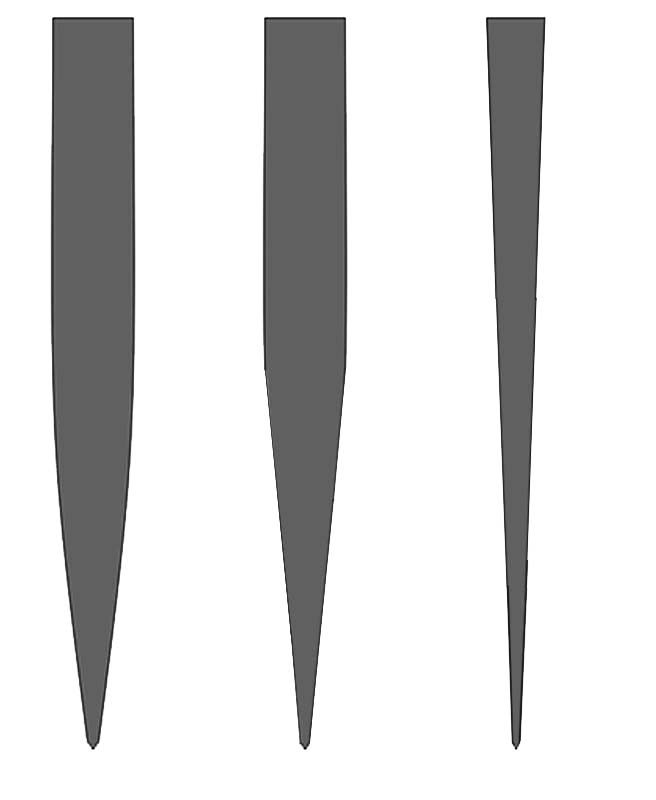

A knife’s cross-section is wedge-shaped: the edge is thin, and it gradually becomes thicker toward the spine. If you keep sharpening only at the same angle on the very edge, the blade will slowly grow thicker at the tip, making it dull. Eventually, it may reach a point where no matter how much you sharpen, it won’t cut properly.

Japanese knives are made very hard through special heat treatment. This allows them to hold a thin, sharp edge without collapsing. But if the edge is improperly ground and thickened, this advantage is lost.

To prevent this, professional sharpeners adjust not only the edge but also the overall thickness and shape of the blade. Each knife has a slightly different form, often with subtle warps or quirks. A skilled sharpener must take all of these into account, applying technique and judgment to bring out the knife’s full performance.